Why Metal?

ISSUE 0001

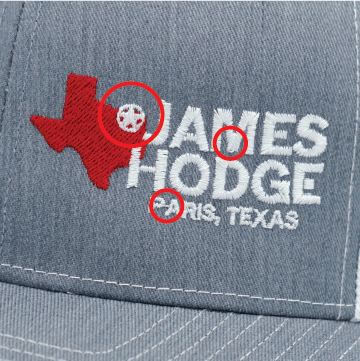

The traditional embroidery process, which used a combination of looms and hand embroidery, dates back to the mid-1800s. While we have to give credit to its longevity in merchandise and apparel, we also saw a huge need for innovation.

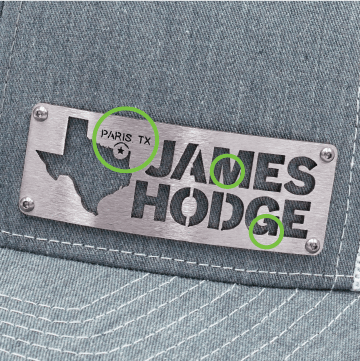

Here at BadgeCaps, we utilize a CNC laser to cut our stainless steel badges with the ultimate precision. The laser has the ability to cut even the smallest details in your logo or design which means we don’t have the same limitations in scale or materials as embroidery.

WHY METAL

Traditionally, metals and their traits like hardness, melting point, and color were a pretty straightforward way to differentiate their utility. However, metals have become highly specialized for specific use cases with modern materials.

As we began specializing these metals, carbon was added to iron to increase its hardness and thus create better, more long-lasting tools. This is referred to today as mild, or carbon steel. However, carbon steel will rust and stain with corrosion without regular maintenance and care, and must be heat treated to harden for tool use, or to hold an edge.

To avoid this, stainless steel uses an alloy of iron and chromium, which gives it its corrosion resistant qualities. This naturally occurring metal, mined as chromite, is incredibly hard — the 3rd hardest element after diamond and boron. Chromium is also brilliantly shiny. Once mixed into stainless steel, it has a specular reflection rate of 40%-60% after polishing. Almost as reflective as a traditional commercial mirror! All of these features are what make this material perfect for our BadgeCaps.

We use exclusively 16ga (0.06”) 316 Grade stainless steel, which adds molybdenum to the alloy to further increase corrosion resistance. This is sometimes referred to as “marine grade” because of its excellent weather resistance in coastal applications. It is non-magnetic, and will not become brittle in extreme heat — the cap may not survive a fire or being lost at sea, but the badge and hardware certainly will!

For more detailed information about the different types of stainless steel, check out this video by AZO Materials for an extensive breakdown.

CUTTING PROCESS

High tech materials require high tech tools! In the 1950s metal on metal shearing was left behind in favor of plasma arc cutting. This process uses a pressurized gas fuel source ignited by an electric spark. An operator was required to control the torch head by hand, following a template. The medium being cut must be electrically conductive to support the arc for ignition, and the ionized gasses emit radiation and are blindingly bright, so protective gear and eye protection is also required. Computer controlled plasma tables have been at the top of the game for a long time — until now!

With our high power precision laser, there is almost no limit to the types of materials you can use, or the level of detail. The fiber optic laser uses a light that is transferred through a fiber optic cable and amplified. Then, the beam is straightened and focused using glass lenses that concentrate it onto the material to be cut.

Whereas plasma superheats the metal and melts it away, our laser’s precision beam of light literally vaporizes the material away at a rate of 400 inches per minute, or over half a foot per second. This allows for much higher levels of precision at speed. The tolerances achieved are much tighter — by a factor of four (+/- 0.005” vs plasma +/- 0.02″). The cut path (or kerf size) is also much smaller, nearly half that of plasma.

This allows us to design artwork that is incredibly intricate and detailed, leaving connecting lines as small as 0.01”. No more compromising on your vision! Not to mention the energy savings, as a laser is much more energy efficient and produces no waste gasses.

FINISHING

After cutting, the badges go to finishing where they are hand inspected one by one. We look for consistency, clean cuts, and to remove any material that didn’t fall free during the cutting process. They are then sanded smooth to maximize the way they catch the light, and then are bent to spec on our press break. From there they go to powder for a fresh coat of paint, or directly to assembly to be placed onto the caps.

Embroidery has had its time in the limelight – it’s time to bring your merch into the 21st century and beyond! With our own in-house process and high powered laser, we are ready for the future. With top of the line equipment, a cutting edge process, and premium materials, we’re here to help take your brand to the next level. Much like a celebrity walking through LAX… it’s hard to wear a BadgeCap and go unnoticed. When you take the plunge into upping your merch game, be prepared for people to start noticing.